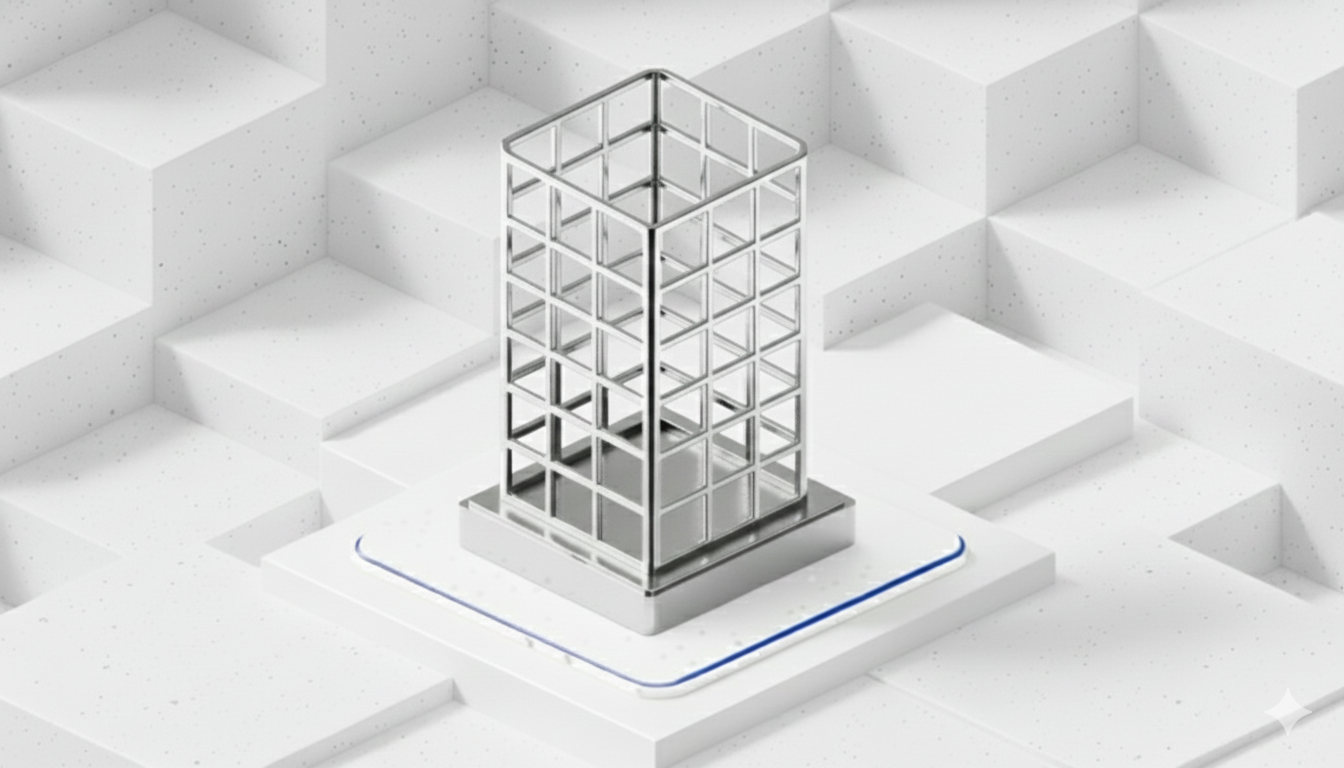

BIM 3D is a 3D building information model that includes element specifications, materials, costs, technical parameters, and up-to-date construction standards.

This format allows engineers, architects, and the client to work with the project as a living digital prototype, where everything is interconnected and updated automatically.

Why do we need BIM 3D?

- an accurate understanding of the future object even before construction begins;

- reduction of errors and conflicts in design documentation;

- automation of calculations and specifications;

- a unified environment for architects, designers, engineers;

- transparency of cost and materials;

- the basis for subsequent levels of BIM: 4D, 5D and beyond.

Where it is applied

BIM 3D is used at all key stages of the building life cycle:

1. Pre-project studies

– concept, sketch, space-planning solutions;

– technical and economic indicators;

– analysis of the site and construction conditions.

2. Design stage

– development of drawings and technical documentation;

– automated calculations;

– generation of estimates and specifications;

– quick adjustments when the solution changes.

3. Construction stage

– visualization of the progress of work;

– quality control;

– checking the intersections of engineering systems;

– management of volumes, materials, and logistics.

4. Operation and maintenance

– working with up-to-date equipment data;

– repair forecasting;

– energy efficiency optimization;

– integration with BMS systems.

What does BIM 3D offer to the client?

- Reducing the cost and time of construction.

- Eliminate most errors before starting work.

- A clear data structure that can be used for 10-30 years.

- Ready-made foundation for BIM 4D (scheduling), 5D (cost), etc.

How we work

-

Collection of initial data and formation of technical specifications

During the first stage, all available materials are collected: plans, drawings, standards, client requirements, and potential project constraints. The goals of the digital model are defined—from visual design to a fully parameterized BIM for expert review and operation. At this stage, the level of detail, the list of engineering systems, and the required format of the final data are agreed upon. All of this is formalized into a transparent technical specification, which sets the scope and depth of the future work.

-

Site survey: laser scanning, aerial photography, measurements

Next, a physical survey of the building or site is conducted. 3D laser scanning captures millions of points and creates a precise cloud, and, if necessary, drones capture facades, roofs, and hard-to-reach elements. The resulting data is compared with archival drawings, identifying discrepancies, deformations, and hidden components. At this stage, an objective digital foundation is created, from which the design can be built without the risk of errors.

-

Point cloud processing and basic 3D geometry construction

After the survey, the point cloud is denoised and converted to a unified coordinate system. Based on this data, a precise geometric model of the object is created: walls, columns, floors, openings, and roofing. At the same time, utility systems are linked and structural components are refined. The model undergoes an initial collision check to avoid intersections and inaccuracies in subsequent stages.

-

Development of a BIM model with the inclusion of 4D and 5D if necessary

Once the geometry is ready, a complete building information model is created. It includes structural elements, utility systems, equipment, and detailed parameters for each object—materials, specifications, manufacturers, and costs. If necessary, the model can be expanded with 4D functionality, when linked to the construction schedule, and 5D functionality, when cost, resource, and budget calculations are added. Thus, BIM becomes a planning and control tool, not just a visualization tool.

-

Preparation of design, working and executive documentation

At this stage, the model is used as a source of accurate documentation. Drawings, plans, sections, specifications, bills of quantities, and cost estimates are automatically generated from it. Any discrepancies between the model and the documentation are resolved, and the final materials are prepared in the required formats—IFC, DWG, PDF, XLSX, and others—depending on the requirements of the expert review or contractors.

-

Transfer of the digital model to the customer and commissioning

At the final stage, the client receives a coordinated BIM model containing the architecture, structure, engineering systems, equipment, and control data. The model can be integrated with operational systems and used for building maintenance, connecting sensors, updating parameters, or planning future renovations. If necessary, data is maintained and updated during operation.