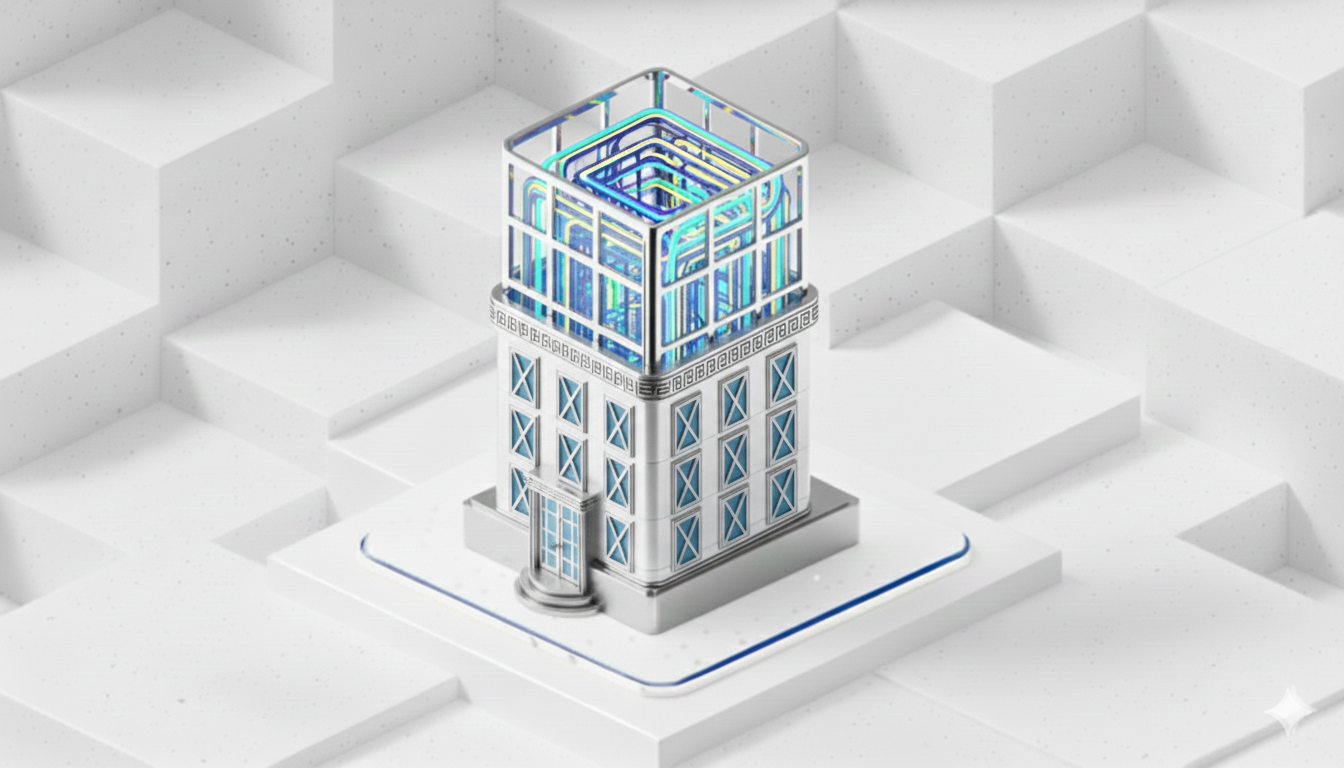

What is BIM 5D?

5D BIM is a model that adds cost to geometry (3D) and time (4D) .

Each design element receives:

— price,

— link to estimate,

— budget impact,

— financing schedule,

— resources, equipment, and logistics.

In other words, this is not a beautiful visualization , but a digital version of the future construction project with money, deadlines, and risks built right into the model.

Why a 3D model alone doesn’t solve anything

Although BIM has long proven its effectiveness, many investors still consider 3D models “expensive toys” that cease to be useful once actual construction begins.

The problem isn’t BIM—the problem is that a conventional design model is unsuitable for construction management .

That’s why we’re transforming BIM into a CIM—a construction information model —that’s already in use on-site, not in a presentation.

CIM: A Model That Can Actually Be Built

The transition from BIM to CIM is a transformation of the model to suit production logic.

CIM takes into account what the design model fundamentally cannot do:

1. Time and schedule

Each element knows exactly when it should appear on the site.

2. Cost and financing schedule

Any change in the model is immediately reflected in the budget and cash flow.

3. Technology, mechanisms, equipment

The loading of mechanisms, work shifts, and task sequence are planned.

4. Temporary structures and logistics

Scaffolding, storage areas, temporary roads, and site restrictions are taken into account.

5. Increased detail of decisions

What is “good enough” in a project becomes precise production instructions in CIM .

6. Reconfiguring the model for contractors’ work

The model is assembled not “as beautifully as possible”, but as it is actually built .

What does an investor get from virtual construction (VDC)?

1. Visibility of the most expensive stage

Construction is the most expensive stage of the investment cycle.

VDC makes it transparent , understandable, and controllable.

Even an untrained person can see

what is being built,

the sequence in which it’s being built,

and where bottlenecks arise.

The general contractor can prove their competence before entering the site .

2. Full control over the status of each element

The model shows everything:

whether working documentation is available,

the status of the element,

whether it has been accepted by technical supervision,

and whether there are any risks to the schedule and budget.

No gray areas or “well, we’re working on it.”

3. Understanding construction processes and conditions

You can assess:

– the tightness of the conditions,

– the structure of logistics,

– the overlap of contractors,

– the realism of the schedules.

Construction ceases to be “living chaos” – it can be modeled and optimized in advance.

The benefits of 5D BIM in one sentence

This is a tool that allows the investor to see in advance how much construction will cost, how it will be carried out, where problems will arise and how to resolve them before money flows to the site .

5D is the basis for efficient modern construction

In essence, BIM 5D transforms a project into a manageable digital product:

– accurate,

– predictable,

– transparent,

– controllable.

How we work

-

Collection of initial data and analysis of design documentation

At this stage, all initial requirements are captured: working drawings, estimates, schedules, site constraints, equipment and contractor data. The structure of the future 5D model, its level of detail, and the logic for its further assembly are determined. A preliminary risk assessment is conducted, along with potential divergences between the design model and reality.

-

Survey of the site and clarification of actual conditions

If necessary, laser scanning, aerial photography, or technical inspection are performed. The actual environment is compared with the existing drawings. This step eliminates discrepancies between the documentation and the actual site, ensuring that the future model is not based on erroneous data.

-

Formation of a basic 3D/4D model for the transition to CIM

An up-to-date 3D model of the site is created, to which a timeline is linked: the sequence of construction work, stages, installation zones, and site accessibility. The model begins to "live" in time, depicting real-life construction scenarios, including installation, temporary structures, and site organization.

-

Integration of cost and resources – formation of a complete 5D model

After setting up the time component, an economic block is added to the model: linking estimate data, budget items, element costs, and the financing schedule. Any change to the model automatically affects the timeframe and budget. Resources, equipment operation, delivery schedules, and contractor workloads are all taken into account.

-

Model optimization and construction scenario analysis

The completed 5D model is used to test various implementation options: reordering stages, changing logistics, reallocating resources, and adjusting the schedule. This step identifies bottlenecks, conflicts, risks, and suboptimal solutions. The model shows how to best organize the construction in terms of cost, timeframe, and site conditions.

-

Preparation of conclusions, reports and production documentation

The model generates refined schedules, bills of quantities, cost adjustments, financing scenarios, and visual reports for contractors and investors. Documentation becomes transparent: each element has a status, cost, and specific timeline.

-

Transfer of the CIM model to the customer and construction support

The final 5D model is handed over to the client as a construction management tool. The model can be updated as work progresses, recording deviations, analyzing risks, and generating forecasts. If necessary, the team monitors the construction process, ensuring data accuracy, synchronization of the model with actual processes, and updating schedules.