Time built into the project

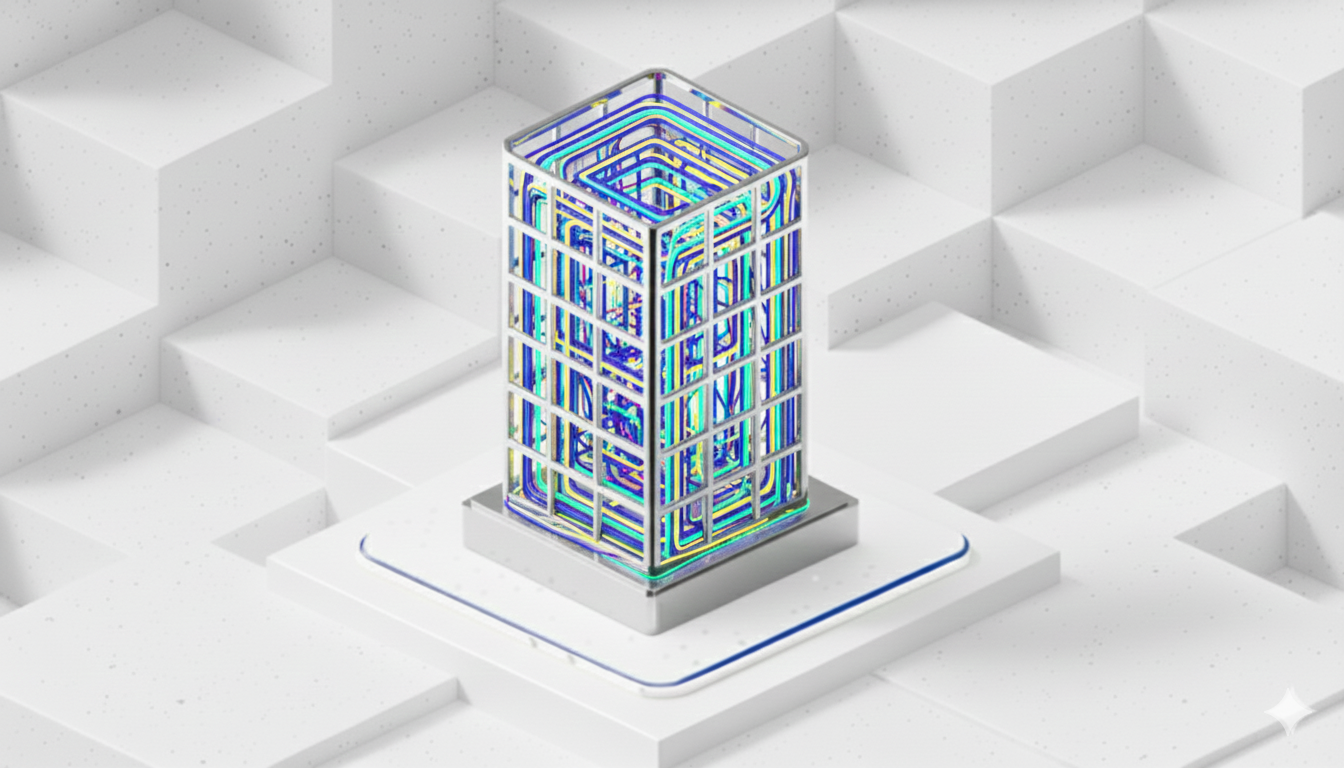

4D BIM modeling combines a 3D model of a facility with a construction schedule. Each element is assigned a location in time , not just its geometry and parameters.

The result is a dynamic digital construction simulation that replaces Excel plans, verbal agreements, and “hopefully” approaches.

Why this changes construction management

4D BIM allows you to verify the feasibility of deadlines , model the work sequence, and identify potential conflicts before going on-site. This reduces the risks of

delays,

cost overruns,

and equipment downtime.

During the preparatory stage, such a model proves the project’s feasibility and provides a significant advantage in tenders.

Problems are visible in advance

During the design stage, a 4D model identifies structural and logistical bottlenecks: passageways, assembly areas, delivery schedules, and contractor overlaps.

This helps optimize the workflow and ensure balanced resource utilization , eliminating chaos and competition between teams.

Real-time monitoring

During construction, 4D BIM becomes an operational management tool :

comparing actual data with plans,

recording deviations,

predicting risks,

and making instant decisions.

Construction ceases to be a “black box.”

One truth for all participants

4D BIM creates a single source of truth : designers, general contractors, subcontractors, and the client all work within the same model and timeline.

This reduces disputes, improves control, and makes communication transparent.

Technology of the future

With the advent of IoT, big data and AI, time-based models are becoming the standard: construction will be planned and controlled as a highly accurate digital system , rather than a chain of guesses.

How we work

-

Formulation of goals and collection of initial data

First, the 4D model's objectives are defined: from a visual check of deadlines to a detailed construction plan that takes into account resources, supplies, and logistics. Technical specifications, a 3D model of the facility (or its creation is commissioned), work schedules, building codes, and the requirements of future contractors are compiled.

-

Preparation of an up-to-date spatial model

If the original geometry is insufficient, laser scanning or site surveying is performed. Using the point cloud, a precise 3D model is created or refined, which will serve as the basis for the schedule.

-

Project analysis and calendar planning

The entire scope of construction work is structured, from preparatory stages to finishing. Dependencies between tasks, potential bottlenecks, risk areas, and equipment and personnel requirements are identified. The plan is cleared of inconsistencies and prepared for alignment with 3D geometry.

-

Integrating the schedule into the BIM model and creating a 4D simulation

Model elements are linked to the timeline, and the sequence of structures, installation operations, and utility systems is established. At this stage, the construction logic becomes clear: floors that are behind schedule, areas crossed by contractors, and operations that require rescheduling.

-

Analysis, optimization and risk elimination

The 4D model is checked for time conflicts: logistical conflicts, failure to complete installation within the required timeframe, crew overlaps, and sequencing errors. The plan is adjusted, the workload is distributed evenly, and the temporary model becomes a working planning tool.

-

Document preparation and integration with the management system

The model generates schedules, statements, construction visualizations, and reports for the general contractor and client. If necessary, data can be exported to formats compatible with Primavera, MS Project, or corporate systems.

-

Transfer of the model to the customer and support during the construction process

The completed 4D model is handed over to the client along with operating instructions. During construction, the schedule can be updated, actual construction compared to the plan, deviation monitoring, schedule recalculation, and operational management can be performed.